Control system Betomat (2020)

By the end of this year, we realized a special solution for our radio control for the company Bitschnau Gleit- und Schalungstechnik in Nenzing for their Betomat. With our remote control, the agitator and the dosing of the concrete can be controlled by a hydraulic unit. For the 6 Betomats, we programmed our own control system, which was adapted to the requirements and tasks of the machine.

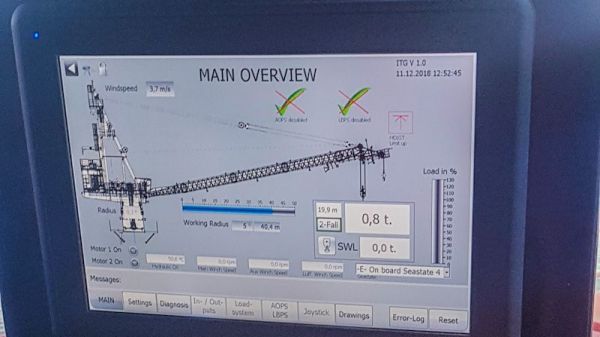

Modification of 2 cranes on the platform Seafox 4 (2020)

This year we realized a special project on the platform Seafox 4 in the North Sea. 20 years ago we were on this platform for the first time to convert the cranes - this was the first project of Greussing. Now it was time again to modernize the two 45 year old cranes. Two of our employees travelled to the platform to check what had to be done on the cranes. For 1 month they worked on the platform and renewed the control of the cranes. One of the cranes got a new gearbox and two new hydraulic pumps, the other crane had its gearbox redone. After the reconstruction the cranes were running better than ever before.

Conversion of a crane control system on a wind farm in Denmark (2020)

This year we renewed the crane control system on a transformer platform in Denmark. Before our rebuild, there were constant problems with the crane, which severely affected the crane availability. The crane control system was brought up to the latest electrical and hydraulic standards and now again meets the specified safety regulations.

Through our conversion we were able to achieve the following advantages for the customer:

- Downtimes were minimized

- The crane is now safe to run

- Speed could be increased by ¼

Reconstruction of a ship crane control system (2019)

On a ship's crane old electronic & thyristor controls were replaced with new direct current drive parts. The old control system was very prone to errors and spare parts for a repair were hard to get.

Our conversion made the daily life of the whole ship crew easier, because now less invidual parts were used, which can be bought without problems and in case of a failure it is easier and faster to find the fault.

Control technology for plastic press & injection molding machines (2017)

We programmed a control system for a plastic press and put it into operation on site. In addition to the programming, a suitable switch cabinet was built for the control of the machine. For 3 further injection moulding machines a new control system was developed, which has a recipe management for different moulds.

Safety control for ship crane in Norway (2019)

In Norway, a ship crane repeatedly failed. There were problems with the visualization and error messages were not displayed correctly. These errors meant that the safety regulations of the control system were not met. Therefore we installed our software on the existing control system and put it into operation on site. The new safety controller allows an improved control for safety-relevant functions and by visualizing the error messages, errors are eliminated as quickly as possible, because you know exactly where the error is.

New explosion-proof control system for a crane on an oil rig in Norway (2016)

In this project we renewed the complete hydraulics and control system for the crane that moves the drill pipe of the drilling platform. Our explosion-proof control system drives the hydraulics of the crane. We also installed our radio control and motors in an explosion-proof version.

Contact

Greussing Crane Service

August Greussing

Bersbuch 745

A-6866 Andelsbuch

+43 5512 26321

office@kranservice-greussing.com

VAT-No.: ATU57386527

Crane conversion, Holland (2021)

We modified a crane on an offshore platform off the coast of Holland. We renewed the entire control system and equipped the operator's cabin with a new control panel. In addition to the control system, new hydraulic components were installed and new cables were layed. A rotary encoder developed by us and new switch cabinets were also installed. Since the crane is located in a hazardous area, all components were installed in explosion-proof design.